KINETICS & REACTOR DESIGN

INTERGRATED PROJECT 2015

(GROUP 20)

Desired Reactor

What is the type of reactor to be used?

Fluidised Bed Reactor (fast pyrolysis)

Overall view of the fast pyrolysis (fluidized bed reactor) process

Bubbling fluid beds, usually referred to as just fluid beds have the advantages of a well understood technology that is good temperature control, simple in construction and operation and very efficient heat transfer to biomass particles due to high solids density. A typical configuration is with quenching cooler and also electrostatic precipitators that are more widely used in laboratory systems to obtain the bio oil and purified bio gas respectively. Fluid bed pyrolysers give consistent and good performance with high liquid yields of typically 70-75%wt. from biomass on a dry feed basis. In order to achieve high biomass heating rates, we need small biomass particle sizes of less than 2-3 mm, and the rate of particle heating is usually the rate limiting step. Residence time of solids and vapors is controlled by the fluidizing gas flow rate and is higher for char than for vapors. As char acts as an effective vapor cracking catalyst at fast pyrolysis reaction temperatures, rapid and effective char separation/elutriation is important. It is usually achieved by entrainment and ejection and then followed by separation in one or more cyclones so careful design of sand and biomass/char hydrodynamics is important.

What is the size of the reactor?

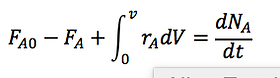

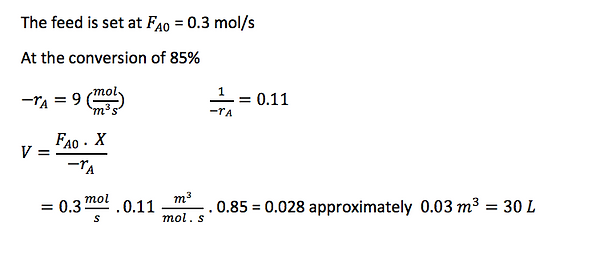

General Mole Balance :

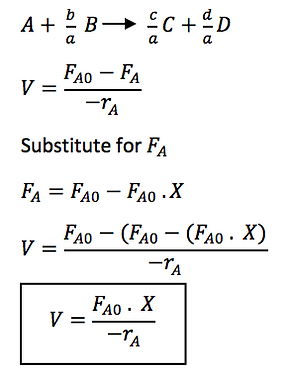

CSTR (Design Equation) :

This reaction is first order (irreversible reaction)

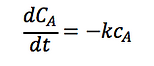

The material balance for a constant volume reactor gives

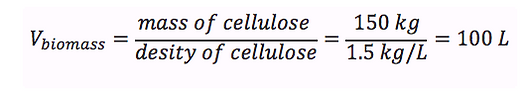

Volume of biomass :

Operating temperature and pressure?

The approximate operating temperature for fast pyrolysis using fluidized bed reactore is around 400-550 C. The operating pressure is ranged between 1-20 bar.

Does it require any heating or cooling? How do you provide that?

Fast pyrolysis is a high temperature process in which the feedstock is rapidly heated in the absence of air, vaporises and condenses to a dark brown mobile liquid which has a heating value of about half that of conventional fuel oil. While it is related to the traditional pyrolysis processes used for making charcoal, fast pyrolysis is a more advanced process that can be carefully controlled to give high yields of liquid. The essential features of a fast pyrolysis process very high heating and heat transfer rate that requires a finely ground biomass feed and rapid cooling of the fast pyrolysis vapours to give the bio-oil product. are The main product, bio-oil, is obtained in yields of up to 70% wt on dry feed,together with by-product char and gas which is used within the process so there are no waste streams.

Constructing an industrial scale fluidized bed reactor for fast pyrolysis of biomass requires consideration for sufficient heat supply. The fast pyrolysis can only be accomplished if high temperature in the bed material can be maintained. We accomplished this by introducing oxygen mixed with the fluidizing gas. However, other solutions can be use, these include:

1) Heat supplied by pre-heated fluidizing gases

2) Heat supplied by the reactor walls, through convection and radiation

3) Pipes or channels inside the fluidized bed, which supplies heat from a secondary reactor where pyrolysis char or gas is combusted

Produce a mechanical drawing of the reactor

Cost of the reactor

-

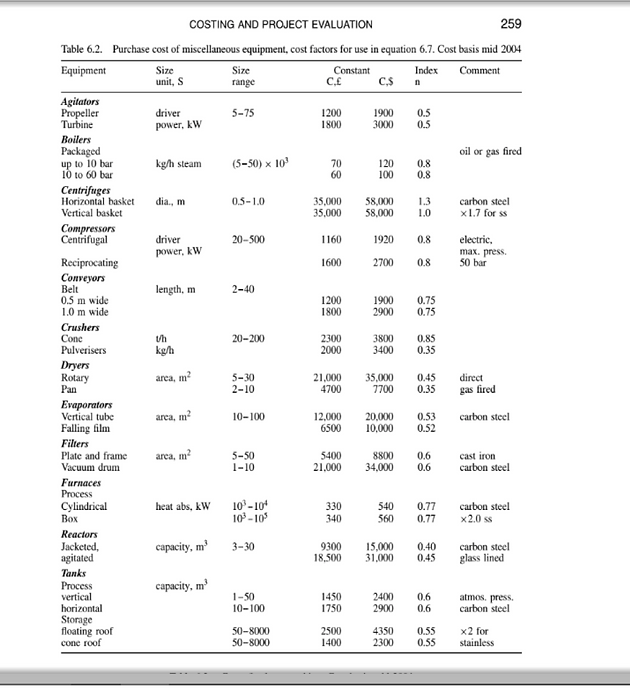

Although the our volume doesn’t meet the minimum requirement of size range, we can use a reactor of 3m3 in our process

-

Assuming the reactor is a batch reactor, using this figure in Coulson & Richardson Chemical Engineering Design Volume 6 with the formula :

Where :

S is the characteristic size parameter

C sis the cost sonstant from the table above

n is the index for that type of equipment

The cost of the equipment is :

References

Prins W. In: Bridgwater AV, editor. Fast Pyrolysis of Biomass: a Handbook

Volume 3, Newbury: CPL Press; 2005, 207-216

Di Blasi C. In: Bridgwater AV, editor. Fast Pyrolysis of Biomass: a Handbook

Volume 3, Newbury: CPL Press; 2005, 121-146

Zafar.S. (January 15, 2015). Biomass Pyrolysis Process. Retrieved July 30, 2015 from http://www.bioenergyconsult.com/biomass-pyrolysis-proces

Palma, Marco A., James Richardson, Brad E. Roberson, Clyde Munster, and Joe Outlaw. "Economic Feasibility of a Mobile Fast Pyrolysis System for Sustainable Bio-crude Oil Production." International Food and Agribusiness Management Review 14.3 (2011): 16. Print.

French. R., Czernik. S., (August 11, 2009). Catalytic Pyrolysis of Biomass for Biofuels Production. Retrieved July 30, 2015 from http://www.sciencedirect.com/science/article/pii/S0378382009002392