KINETICS & REACTOR DESIGN

INTERGRATED PROJECT 2015

(GROUP 20)

Transfer Function

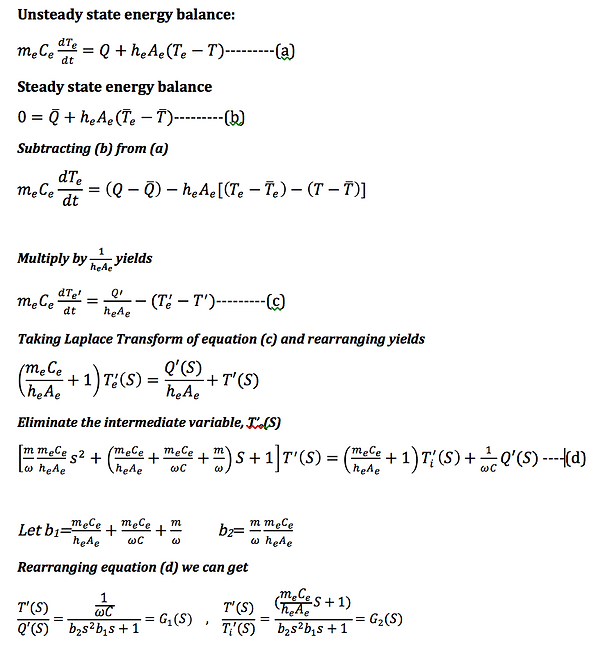

Transfer function of the reactor

A fluidised bed reactor consists of an electrical heater to maintain the required temperature in the reactor.

The transfer function can be initiated into two parts : the reactor and the heater

The Reactor :

The Heater :

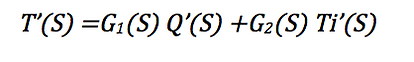

By implementing the superposition principle, effects of simaltaneous changes in both input temperature and heat energy is expressed below by the transfer function :

The order of the transfer function

First order.

The control variable(s), manipulated variable(s), and possible disturbance variable(s) for the reactor

Controlled Variable (CV) : Flow rate of biogas, flow rate of bio-oil, flow rate of char (solid)

Composition of biogas, composition of bio-oil, composition of char (solid)

Manipulated Variable (MV) : Biomass feed flow rate, kg/hr

Disturbance Variable (DV) : Operating pressure, operating temperature, catalysts

The type of control alghorithm (P, PI or PID)? Why?

The PID controllers is recommended. PID controller is a combination of proportional, integral and derivative controller, therefore it combines all the advantages of these controllers. As shown in the graph below, a PID controller has lower oscillation and offset occurs. In the PID controller, the integral control output will detect the error signal over time, resulting in a reduction in response time.